3D 打印 Marlin 固件

Marlin 是一个 3D 打印的开源固件。Marlin 固件驱动控制板、读取 G-code 码执行打印的工作、控制步进电机打印出实体、控制挤出机及加热板的温度、侦测挤出机及加热板的温度作为控制温度的回馈、有读写 SD 卡的功能、支持 LCD 显示打印的信息。

Marlin is an open source firmware for the RepRap family of replicating rapid prototypers — popularly known as “3D printers.” It was derived from Sprinter and grbl, and became a standalone open source project on August 12, 2011 with its Github release. Marlin is licensed under the GPLv3 and is free for all applications.

From the start Marlin was built by and for RepRap enthusiasts to be a straightforward, reliable, and adaptable printer driver that “just works.” As a testament to its quality, Marlin is used by several respected commercial 3D printers. LulzBot, Prusa Research, Creality3D, BIQU, Geeetech, and Ultimaker are just a few of the vendors who ship a variant of Marlin. Marlin is also capable of driving CNC machines and laser engravers.

One key to Marlin’s popularity is that it runs on inexpensive 8-bit Atmel AVR micro-controllers - Marlin 2.x has added support for 32-bit boards. These chips are at the center of the popular open source Arduino/Genuino platform. The reference platforms for Marlin is an Arduino Mega2560 with RAMPS 1.4 and Re-Arm with Ramps 1.4.

As a community product, Marlin aims to be adaptable to as many boards and configurations as possible. We want it to be configurable, customizable, extensible, and economical for hobbyists and vendors alike. A Marlin build can be very small, for use on a headless printer with only modest hardware. Features are enabled as-needed to adapt Marlin to added components.

Main features

- Full-featured G-code with over 150 commands

- Complete G-code movement suite, including lines, arcs, and Bézier curves

- Smart motion system with lookahead, interrupt-based movement, linear acceleration

- Support for Cartesian, Delta, SCARA, and Core/H-Bot kinematics

- Closed-loop PID heater control with auto-tuning, thermal protection, safety cutoff

- Support for up to 5 extruders plus a heated printbed

- LCD Controller UI with more than 30 language translations

- Host-based and SD Card printing with autostart

- Bed Leveling Compensation — with or without a bed probe

- Linear Advance for pressure-based extrusion

- Support for Volumetric extrusion

- Support for mixing and multi-extruders (Cyclops, Chimera, Diamond)

- Support for Filament Runout/Width Sensors

- Print Job Timer and Print Counter

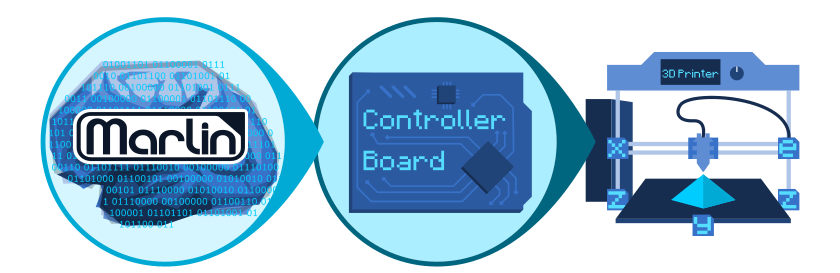

How Marlin Works

Marlin Firmware runs on the 3D printer’s main board, managing all the real-time activities of the machine. It coordinates the heaters, steppers, sensors, lights, LCD display, buttons, and everything else involved in the 3D printing process.

Marlin implements an additive manufacturing process called Fused Deposition Modeling (FDM) — aka Fused Filament Fabrication (FFF). In this process a motor pushes plastic filament through a hot nozzle that melts and extrudes the material while the nozzle is moved under computer control. After several minutes (or many hours) of laying down thin layers of plastic, the result is a physical object.

The control-language for Marlin is a derivative of G-code. G-code commands tell a machine to do simple things like “set heater 1 to 180°,” or “move to XY at speed F.” To print a model with Marlin, it must be converted to G-code using a program called a “slicer.” Since every printer is different, you won’t find G-code files for download; you’ll need to slice them yourself.

As Marlin receives movement commands it adds them to a movement queue to be executed in the order received. The “stepper interrupt” processes the queue, converting linear movements into precisely-timed electronic pulses to the stepper motors. Even at modest speeds Marlin needs to generate thousands of stepper pulses every second. (e.g., 80 steps-per-mm * 50mm/s = 4000 steps-per-second!) Since CPU speed limits how fast the machine can move, we’re always looking for new ways to optimize the stepper interrupt!

Heaters and sensors are managed in a second interrupt that executes at much slower speed, while the main loop handles command processing, updating the display, and controller events. For safety reasons, Marlin will actually reboot if the CPU gets too overloaded to read the sensors.

Printing Things

Modeling

While Marlin only prints G-code, most slicers only slice STL files.

Whatever you use for your CAD toolchain, as long you can export a solid model, a slicer can “slice” it into G-code, and Marlin firmware will do its best to print the final result.

Before Marlin can dream of printing, first you’ll need a 3D model. You can either download models or make your own with one of many free CAD programs, such as FreeCAD, OpenSCAD, Tinkercad, Autodesk Fusion 360, SketchUp, etc.

A high degree of knowledge is needed to model complex objects like a T-Rex Skull, but other objects can be quite simple to model. To get ideas and test things out, explore sites like Thingiverse and YouMagine and print things for fun.

Slicing

Slicers prepare a solid 3D model by dividing it up into thin slices (layers). In the process it generates the G-code that tells the printer in minute detail how to reproduce the model. There are many slicers to choose from, including:

- Cura.

- Slic3r.

- PrusaSlicer (formerly Slic3r Prusa Edition) The new Kid on the block based on Slic3r.

- Simplify3D is a commercial offering.

Printing

Marlin can be controlled entirely from a host or in standalone mode from an SD Card. Even without an LCD controller, a standalone SD print can still be initiated from a host, so your computer can be untethered from the printer.

Host software is available for several platforms, including desktop systems, Raspberry Pi, and Android tablets. Any device with a USB port and serial terminal can technically act as a host, but you’ll have a better printing experience using host software specifically designed for 3D printers. Current selections include:

- Pronterface is an open source host by Kliment.

- Repetier Host is a closed-source host by Repetier Software.

- OctoPrint is an open source host for Raspberry Pi by Gina Häußge.

- Cura is an open source host by Ultimaker. (WARNING: You can no longer manual select com port and speed, your printer needs to be auto detected by Cura)

- Simplify3D includes both a host and slicer.

Many 3D printers ship with a customized version of Repetier or Cura. While this helps to associate the printer brand with a companion piece of software, these versions are usually obsolete and receive few upgrades. We recommend you download the latest generic version of your preferred host software instead.

相关链接

- 官方网站��:https://marlinfw.org

- GitHub 仓库:https://github.com/MarlinFirmware/Marlin